Publication: Simulating and Optimizing Mechanical Equipment for Candy Manufacturing

The food production sector is a significant energy consumer, representing 15.7% of US energy usage. As the world grapples with climate change, industries, including food production, are making strides towards carbon neutrality. Within this context, the manufacturing of soft-jelled candies emerges as a particularly energy-intensive process. This article delves into the intricacies of candy manufacturing and how mechanical equipment can be optimized for energy efficiency.

Technology

Multi-objective Optimization

Link

Coming Soon

Publication

ASHRAE Transactions

Date Published

January 2023

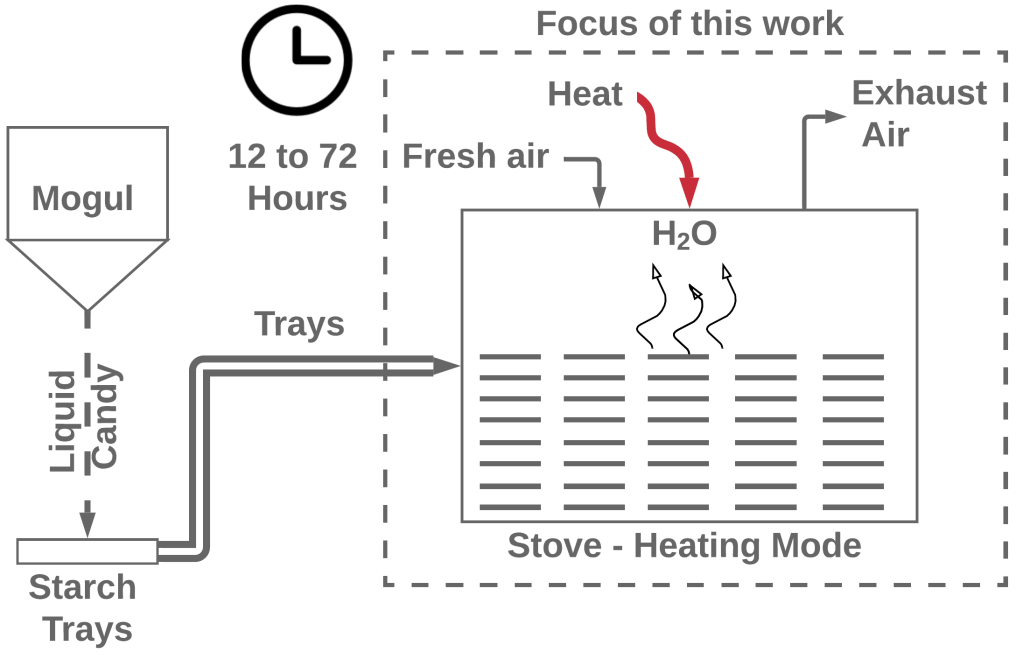

Publication: Energy modeling with meteorological data and multiobjective optimization of a confectionery stove

The food production sector is a significant energy consumer, representing 15.7% of US energy usage. As the world grapples with climate change, industries, including food production, are making strides towards carbon neutrality. Within this context, the manufacturing of soft-jelled candies emerges as a particularly energy-intensive process. This article delves into the intricacies of candy manufacturing and how mechanical equipment can be optimized for energy efficiency.

Technology

Multi-objective Optimization, Energy Modeling

Link

Article Link

Publication

Journal of Food Engineering

Date Published

March 2021

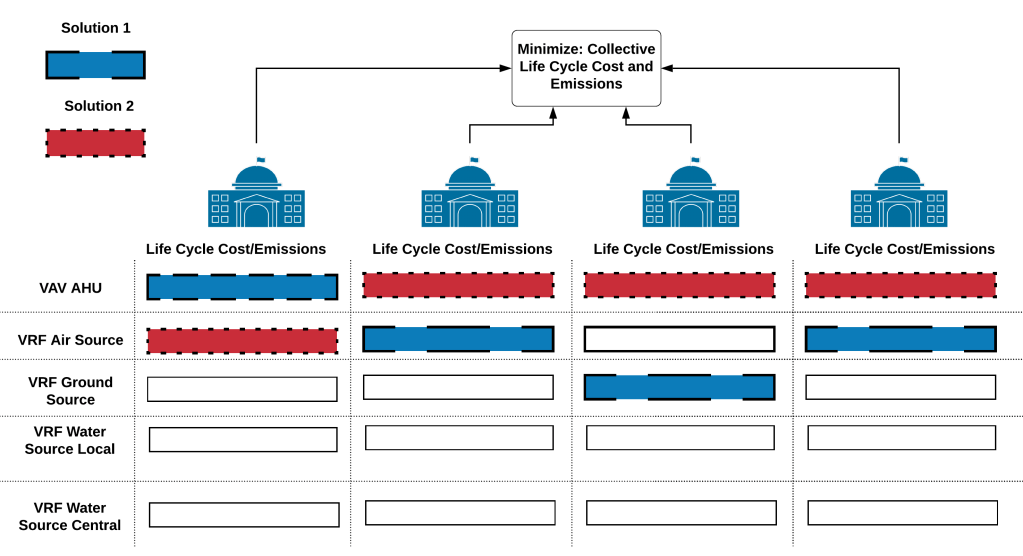

Publication: Incorporating observed data into early design energy models for life cycle cost and carbon emissions analysis of campus buildings

As energy prices increase along with a societal desire for reducing the impact of global warming, it is common for campus decision-makers to consider the life cycle and carbon emissions of future and existing buildings. This work proposes a technique for leveraging observed energy and weather data to represent internal loads for heating, cooling, and occupancy of different building types to simplify the analysis of multiple buildings. Template energy profiles and modular energy models simulate the operation and energy usage of buildings with different HVAC equipment types. This approach makes it possible to evaluate multiple buildings from a broader campus-level perspective. This work proposes a discrete multi-objective optimization framework to select the optimal HVAC system for each building to minimize life cycle cost and emissions. A case study for the University of Utah campus demonstrates the application of the proposed framework to consider a group of new buildings with different principal building activity and size with five different HVAC systems. Results show it is possible to reduce overall carbon emissions of the buildings by 15% while only increasing the life cycle cost by 2.4% by considering a combination of systems rather than a single HVAC system type.

Technology

Multi-objective Optimization, Energy Modeling

Link

Article Link

Publication

Energy and Buildings

Date Published

October 2020

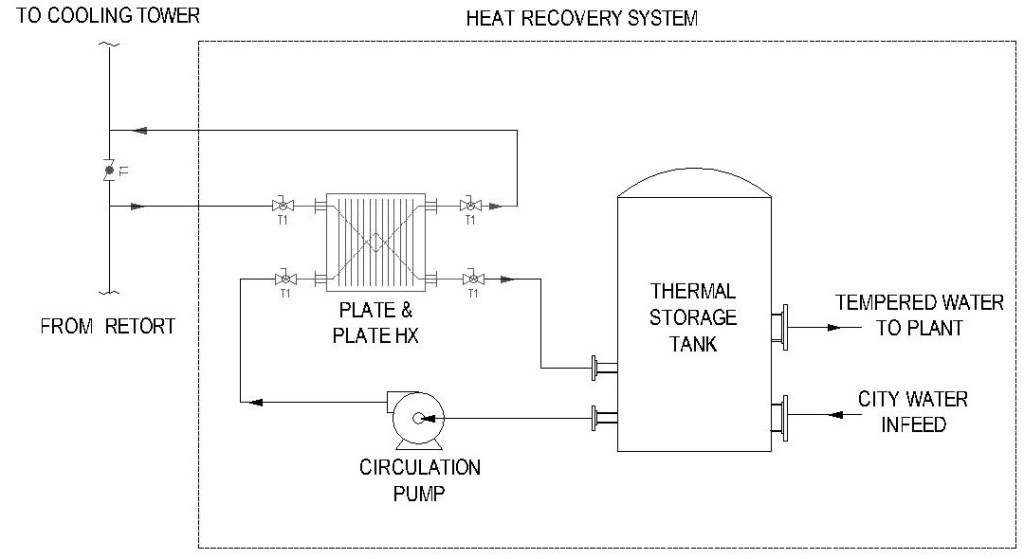

Publication: Demonstrating the Benefit of Multi-Objective Optimization and Clustering for the Design of Waste Heat Recovery Systems

Escalating energy prices and growing consumer concern for sustainable products incentivizes the reduction of energy consumption within the manufacturing sectors. Particularly, the food production industry requires large amounts of heat energy to cook food, of which 9 to 12% is typically wasted. Recovering and reusing waste heat within facilities is a proven method; however, optimizing the waste heat recovery systems (WHRS) can be difficult. Particularly, optimizing WHRS are difficult when process flows vary with respect to time and/or there are multiple objectives desired from the WHRS. Complex systems may be optimized by using a multi-objective evolutionary algorithm (MOEA). The multi-objective design space tradeoffs may then be analyzed using a clustering algorithm to illustrate the cost-benefit of optimizing to one objective versus another. In this work, a case study, using modeled data from an existing cannery, is presented to demonstrate the optimization of the WHRS for the facility. The cannery operates seasonally. During operation raw vegetables and meat are cleaned, cooked, seasoned and canned. A particularly energyintensive piece of equipment is the retort. The retort steam heats cans to 160°F, for pasteurization, and then water cools them to 85°F. A WHRS will be optimized for recovering waste heat from the retort pasteurization zone to heat process hot water. The MOEA will evaluate for economic, energy performance objectives and size restrictions. These goals include: minimizing up-front costs, maximizing the amount of heat recovered and minimizing the floor space required for the system. While optimizing the system, the MOEA adjusts for seasonal variability, batch processing variability, and a wide range of potential food products. The case study demonstrates that MOEA are useful for illustrating the impact of design objectives and designing WHRS systems.

Technology

Multi-objective Optimization, Energy Modeling

Link

Article Link

Publication

ASHRAE Transactions

Date Published

January 2019

Publication: Early Design Phase Energy Modeling And Multiobjective Optimization

In the U.S., buildings have an average life span of 70-75 years (DOE, 2011) and represent 40% of the country’s annual energy use (Energy Information Administration, 2012). Consequently, design choices related to new buildings have a significant and long-lasting impact. In general, it is important to consider energy consumption and cost for the design of every building. However, when buildings are part of a larger campus, a single-building perspective can fall short of identifying how the buildings can interact to reduce their overall energy consumption, cost or emissions. This reduction is only achievable through a multibuilding analysis simulation. One difficulty of performing a multibuilding simulation is that each building is probably only defined conceptually during the early design phase of a large campus. This article will go through one way to simulate, analyze and optimize the mechanical system types for a campus when only building function type, quantities of buildings, and size is known.

Technology

Multi-objective Optimization, Energy Modeling, EnergyPlus

Link

Article Link

Publication

Utah Engineering Council

Date Published

June 2021

Publication: Energy modeling framework for optimizing heat recovery in a seasonal food processing facility

Societal, cultural and economic factors are driving food processors to reduce energy consumed per unit mass of food. This presents a unique problem because time variant batch processing using low to medium grade heat is common in food production facilities. Heat recovery methods may be implemented by food processors to reduce energy consumption; however, temporal variance in the process and utility flow require the development of a robust, easily implemented energy model to accurately determine system effectiveness and economic incentive. A bottom-up modular computational framework is proposed to model the energy consumption of a cannery. The model predicts that the cannery will require 612 kJ gas/kg product produced, which is within the ranges provided in previous literature. Results show that adding a globally optimized indirect heat recovery system will reduce the gas consumption by 6% annually. The proposed framework, used here to represent a cannery, may be adapted to many different types of food processing facilities. With a clear picture of energy consumption by device, and the ability to predict the impact of process modification or heat recovery, plant-level energy usage for food processing may be significantly reduced.

Technology

Optimization, Energy Model

Link

Publication Link

Publication

Applied Energy

Date Completed

November 2018